From Wikipedia, the free encyclopedia/The concept of the Industrial Internet is similar to the idea of Electronic Transaction Monitoring found in the New Paradigm of Transfinancial Economics Blogger Ref http://www.p2pfoundation.net/Transfinancial_Economics

The industrial internet is a term coined by General Electric[1] and refers to the integration of complex physical machinery with networked sensors and software. The industrial Internet draws together fields such as machine learning, big data, the Internet of things, machine-to-machine communication and Cyber-physical system to ingest data from machines, analyze it (often in real-time), and use it to adjust operations.

As of 27 March 2014, the Industrial Internet Consortium (IIC) was founded by AT&T, Cisco, General Electric, IBM, and Intel to bring together industry players—from multinational corporations to academia and governments—to accelerate the development, adoption and wide-spread use of Industrial Internet technologies.[2]

The Union Pacific Railroad mounts infrared thermometers, microphones and ultrasound scanners alongside its tracks. These sensors scan every train as it passes and send readings to the railroad’s data centers, where pattern-matching software identifies equipment at risk of failure.[6][7] Falling prices for computing power and networked sensors mean that similar techniques can be applied to small, common devices like machine tools.[8] In that case scenario, following a 5C architecture defined for Cyber-Physical Systems will help to standardize the use of Industrial Internet in manufacturing and related disciplines[3][9]

As of 27 March 2014, the Industrial Internet Consortium (IIC) was founded by AT&T, Cisco, General Electric, IBM, and Intel to bring together industry players—from multinational corporations to academia and governments—to accelerate the development, adoption and wide-spread use of Industrial Internet technologies.[2]

Contents

[hide]Design Guidelines[edit]

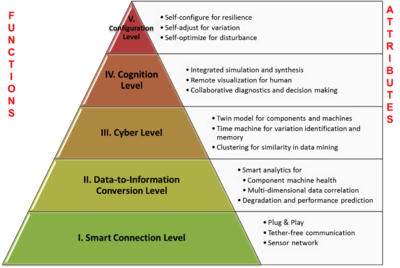

Since the meaning of Industrial Internet is similar to that of Cyber-physical Systems (CPS), the design of an Industrial Internet platform can also follow the “5C Architecture”[3]. “5C” refers to the five levels of designing a CPS, which is much more clear and concrete than the commonly referenced two functional components: advanced connectivity and intelligent data analytics. These five levels are (1) Smart connection; (2) Data-to-information conversion; (3) Cyber; (4) Cognition; and (5) Configuration.Smart Connection[edit]

A necessity of building connection between the cyber space and the physical space is the acquisition of data from industrial equipment. Data might be collected from different sources: add-on sensors, controllers, human inspection, maintenance log, alarm / event systems, etc. One of the challenges at this level is the diversity of equipment types and communication protocols. Machine-to-Machine techniques such as MTConnect[4] are of vital importance to serve as one of the solutions.Data-to-Information Conversion[edit]

The era of Big Data does not promise self-evident insightful information. Instead, it usually means that significant effort has to be taken to “mine” knowledge among a large number of less useful information. Through the development of machine learning, statistical analysis, and data mining techniques, this level of the platform will perform intelligent analysis on the data and bring self-awareness to assets.Cyber[edit]

Cyber level is what fundamentally differentiates CPS or Industrial Internet from conventional data-driven modeling frameworks. The cyber level servers as a central information hub, where information from networked machines or assets is pumped into it, and customized analytics will be performed to extract knowledge of machine conditions over time. These analytics will equip machines with the ability of self-comparison – the foundation of learning from the past. On the other hand, similarities between machine performances and other units can be measured to predict the future behavior – the ability of peer comparison, which brings more accurate prediction.Cognition[edit]

The task of Cognition level is to generate a thorough understanding of the monitored machines or assets, so that the acquired insights can be visualized by users to better support decision-making.Configuration[edit]

Eventually, Configuration level will realize the feedback from Cyber space to the Physical space. Resilience control system (RCS) methodology will be applied to make corrective and preventive decisions to the monitored system.Examples[edit]

The Google driverless car takes in environmental data from roof-mounted LIDAR, uses machine-vision techniques to identify road geometry and obstacles, and controls the car’s throttle, brakes and steering mechanism in real-time.[5]The Union Pacific Railroad mounts infrared thermometers, microphones and ultrasound scanners alongside its tracks. These sensors scan every train as it passes and send readings to the railroad’s data centers, where pattern-matching software identifies equipment at risk of failure.[6][7] Falling prices for computing power and networked sensors mean that similar techniques can be applied to small, common devices like machine tools.[8] In that case scenario, following a 5C architecture defined for Cyber-Physical Systems will help to standardize the use of Industrial Internet in manufacturing and related disciplines[3][9]

See also[edit]

- Cloud-based design and manufacturing

- Big data

- SCADA

- Industrial Ethernet

- Internet of Things

- Machine to machine

- Industrial control system

- Industry 4.0

- Intelligent Maintenance Systems

- Cyber-physical system

References[edit]

- Jump up ^ Leber, Jessica (2012-11-28). "General Electric’s San Ramon Software Center Takes Shape | MIT Technology Review". Technologyreview.com. Retrieved 2013-08-18.

- Jump up ^ Hardy, Quentin. "Consortium Wants Standards for Internet of Things". New York Times. 27 March 2014.

- ^ Jump up to: a b Lee, Jay; Bagheri, Behrad; Kao, Hung-An (January 2015). "A Cyber-Physical Systems architecture for Industry 4.0-based manufacturing systems". Manufacturing Letters 3: 18–23. doi:10.1016/j.mfglet.2014.12.001.

- Jump up ^ Vijayaraghavan, Athulan; Sobel, Will; Fox, Armando; Dornfeld, David; Warndorf, Paul (2008-06-23). "Improving machine tool interoperability using standardized interface protocols: MT connect". Proceedings of 2008 ISFA.

- Jump up ^ Steve Lohr. "The Internet Gets Physical". The New York Times. Retrieved 2013-08-18.

- Jump up ^ Chris Murphy (2012-08-08). "Union Pacific Delivers Internet Of Things Reality Check - Global Cio". Informationweek.com. Retrieved 2013-08-18.

- Jump up ^ Chris Murphy (2012-12-07). "Silicon Valley Needs To Get Out More - Global Cio - Executive". Informationweek.com. Retrieved 2013-08-18.

- Jump up ^ Jon Bruner (2012-10-29). "Listening for tired machinery - O'Reilly Radar". Radar.oreilly.com. Retrieved 2013-08-18.

- Jump up ^ "IMSCenter". IMSCenter.

External links[edit]

- Mark Fell. "Roadmap for the Internet of Things - Its Impact, Architecture and Future Governance" Carré & Strauss, 2014.

- Lohr, Steve. "The Internet Gets Physical" New York Times, December 17, 2011.

- Bruner, Jon. "Defining the industrial Internet" O'Reilly Radar, January 11, 2013.

- Murphy, Chris. "Silicon Valley Needs To Get Out More" InformationWeek, December 7, 2012.

- Loukides, Mike. "To eat or be eaten?" O’Reilly Radar, November 30, 2012.

- N.P., Ullekh. "How GE’s over $100 billion investment in ‘industrial internet’ will add $15 trillion to world GDP" Economic Times, December 16, 2012.

- Smarr, Larry. "An Evolution Toward a Programmable Universe" New York Times, December 5, 2011.

- Evans, Peter C. and Marco Annunziata. "Industrial Internet: Pushing the Boundaries of Minds and Machines" GE white paper, November 26, 2012.

- Bacidore, Mike. "Are your prepared to work in an autonomous plant?", PlantService, March 2013.

- "Industrial Internet 101 - A Beginner's Guide to the Next Industrial Revolution".

- "NSF Industry/University Cooperative Research Center on Intelligent Maintenance Systems"

No comments:

Post a Comment